Business process management examples by function

1. Finance and accounting processes

Typical workflow example: procure-to-pay or order-to-cash

Finance and accounting processes are often among the first areas where BPM is applied. These workflows involve multiple handoffs, approvals, and systems, and even small inefficiencies can create delays, errors, or compliance risks.

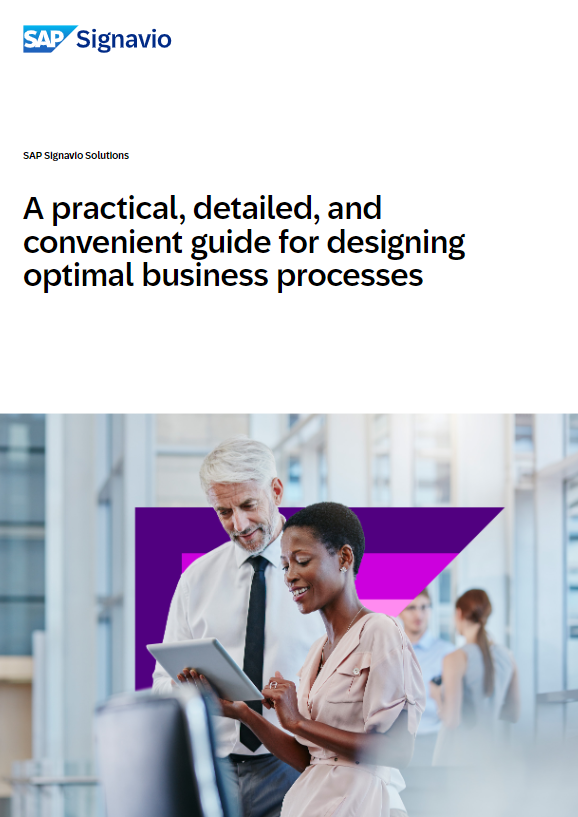

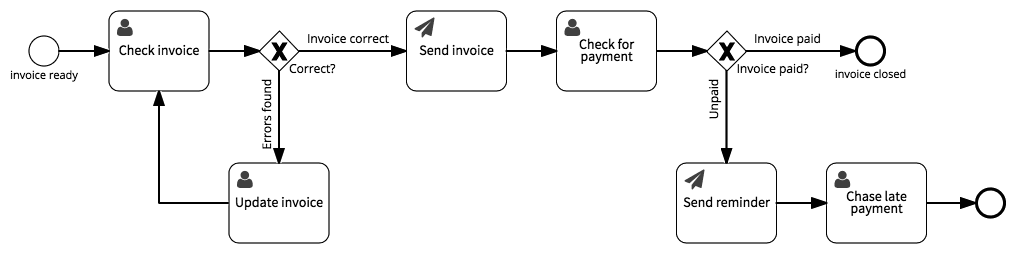

Invoice customer workflow example

You typically see BPM used here when teams struggle with inconsistent execution, unclear ownership, or limited visibility into where transactions get stuck. BPM helps by making the end-to-end workflow explicit, defining responsibilities, and creating a shared view of how finance processes are supposed to run.

In a procure-to-pay workflow, for example, BPM is applied to standardize how purchase requests are created, approved, processed, and reconciled. This reduces manual rework, shortens cycle times, and improves transparency across procurement, finance, and operations. In an order-to-cash workflow, BPM often focuses on reducing delays between order creation, invoicing, and payment collection.

These finance BPM examples usually lead to:

- clearer ownership across finance and procurement,

- fewer manual workarounds,

- more predictable processing times,

- and better visibility into financial operations.

DKB Service shows how BPM was applied to improve finance-related service processes and increase transparency across teams.

2. Human resources and people processes

Typical workflow example: employee onboarding

Human resources processes are another common starting point for BPM, especially in growing or distributed organizations. Workflows such as employee onboarding often involve many handoffs between HR, IT, facilities, managers, and external providers, which makes coordination difficult without clear process ownership.

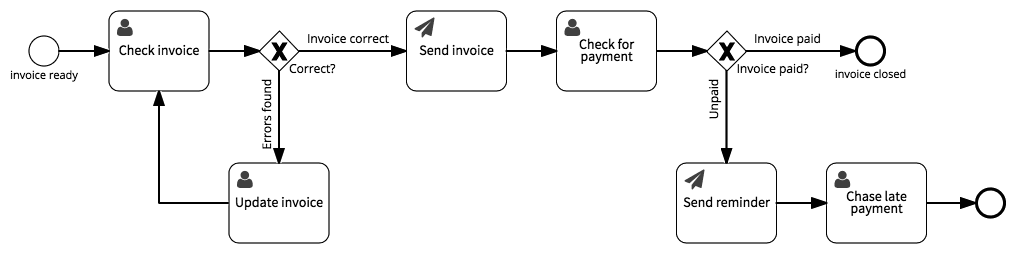

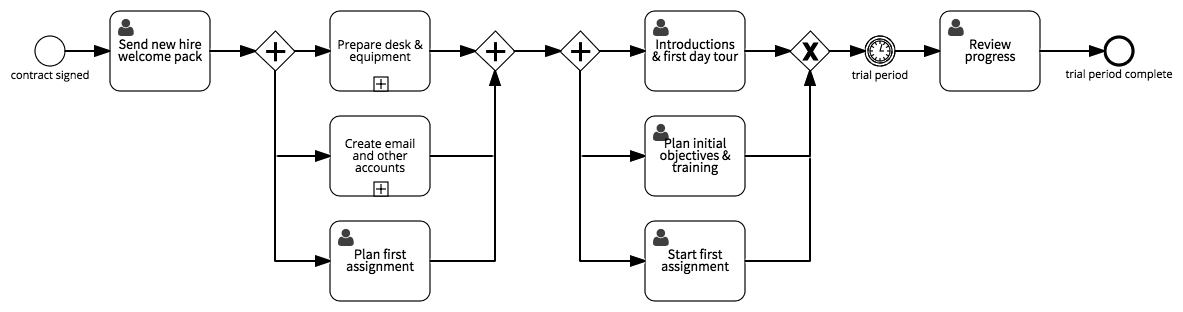

Employee onboarding workflow example

You usually see BPM applied when onboarding experiences vary across teams or locations, when responsibilities are unclear, or when new hires are not productive on time due to missing access, equipment, or information. BPM helps by defining a single end-to-end onboarding workflow that makes dependencies visible and responsibilities explicit.

In an employee onboarding workflow, BPM is used to standardize how hiring information is passed from HR to other teams, when system access is provisioned, and how tasks are tracked before and after a new employee’s first day. This creates consistency while still allowing local or role-based variations where needed.

These HR BPM examples typically result in:

- clearer ownership across HR and support teams,

- more predictable onboarding timelines,

- fewer manual follow-ups,

- and a more consistent experience for new employees.

NSW Department of Education demonstrates how BPM supported the management and standardization of large-scale people and administrative processes.

3. Customer service and case management

Typical workflow example: customer request or claims handling

Customer service processes are often highly visible and directly impact customer satisfaction. These workflows usually span multiple teams and systems, making it difficult to maintain consistent response times and service quality without a clear process framework.

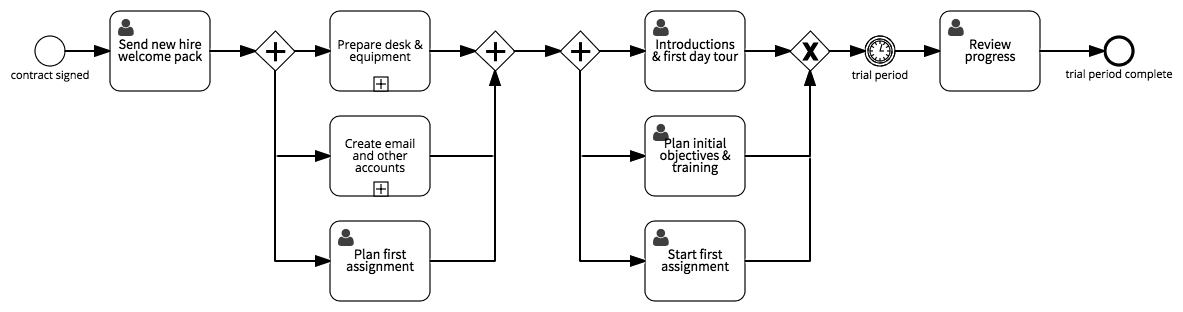

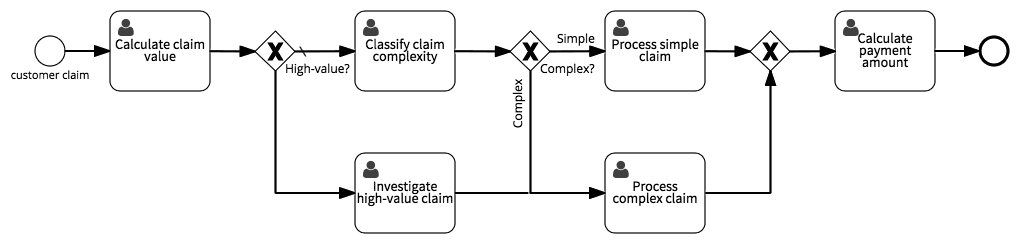

Process claim workflow example

You typically see BPM applied when customer requests are handled differently depending on the team, when cases are handed off without clear ownership, or when service-level agreements are difficult to meet or measure. BPM helps by making the end-to-end case flow explicit and by defining how work moves from intake to resolution.

In a customer request or claims handling workflow, BPM is used to standardize intake, triage, investigation, and resolution steps. It clarifies who owns each stage, how exceptions are handled, and how performance is tracked. This improves coordination between front-office and back-office teams and reduces delays caused by unclear handoffs.

These customer service BPM examples often lead to:

- more consistent service levels,

- improved visibility into case status,

- clearer accountability across teams,

- and better data for service improvement.

Ageas UK shows how BPM was applied to improve customer-facing processes and coordination across teams.

4. Supply chain and operations

Typical workflow example: procure-to-deliver or logistics coordination

Supply chain and operational processes are common BPM candidates because they span many teams, systems, and external partners. Even small inefficiencies can ripple across planning, procurement, warehousing, and delivery.

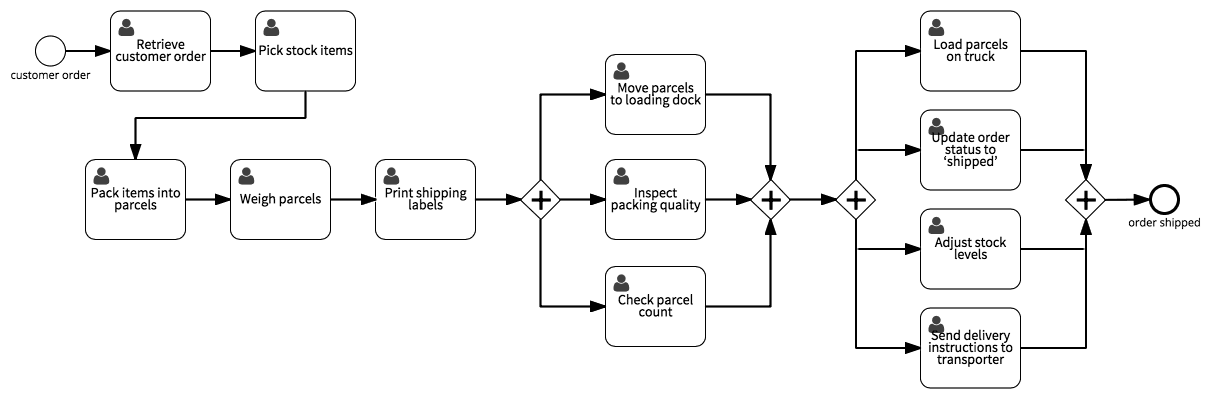

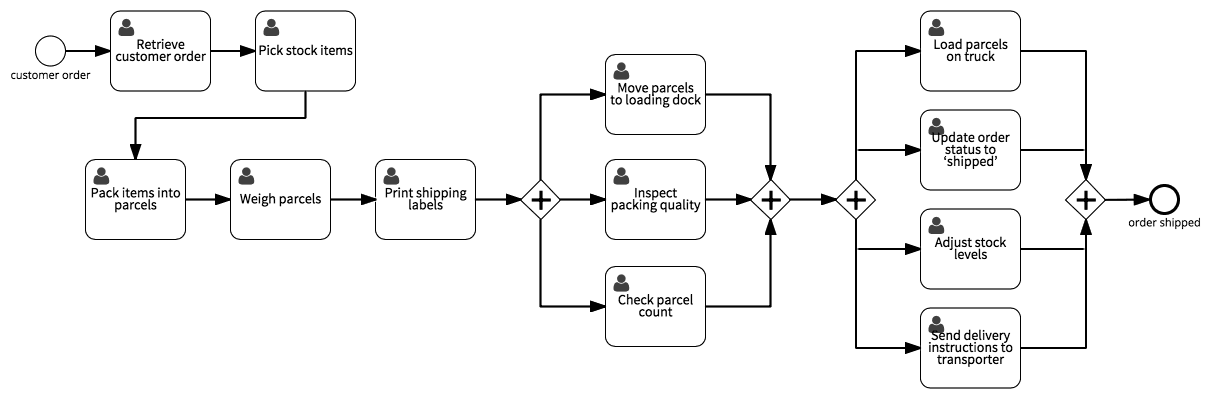

Ship product from warehouse workflow example

You typically see BPM applied when handoffs between functions are unclear, when delays are hard to trace, or when teams lack a shared view of how operational work flows end to end. BPM helps by making dependencies visible, defining ownership across stages, and aligning execution across internal and external parties.

In a procure-to-deliver or logistics coordination workflow, BPM is used to standardize how demand is translated into orders, how suppliers and internal teams are coordinated, and how exceptions are handled. This improves predictability and reduces the effort spent on manual follow-ups and escalations.

These supply chain BPM examples usually result in:

- better coordination across operational teams,

- fewer delays caused by unclear handoffs,

- improved transparency across the supply chain, and more reliable execution.

Ocean Network Express illustrates how BPM supported coordination and transparency in complex, global operational processes.

5. Manufacturing and quality management

Typical workflow example: production quality control or change management

Manufacturing and quality management processes often involve strict standards, multiple approvals, and close coordination between engineering, production, and quality teams. Variations in execution can lead to defects, delays, or compliance issues.

You typically see BPM applied when processes differ across plants or product lines, when quality checks are handled inconsistently, or when changes to production procedures are hard to communicate and control. BPM helps by defining clear workflows, responsibilities, and approval paths that can be reused and governed across locations.

In a production quality control or engineering change workflow, BPM is used to standardize how issues are reported, assessed, approved, and resolved. This creates transparency around decisions, reduces rework, and helps teams understand how changes affect downstream activities.

These manufacturing BPM examples often lead to:

- more consistent quality processes across sites,

- clearer governance for production changes,

- reduced risk of non-compliance,

- and better coordination between engineering and operations.

Diehl Aviation shows how BPM supported standardized and governed processes in a highly regulated manufacturing environment.

Yamaha Motors illustrates BPM usage across complex manufacturing operations.