Process mapping starts with a process’ end goal, and then adds detail that describes the work that contributes to this goal. This article introduces the distinction between ‘bad work’ and ‘good work’ - hassle and value.

This article follows on from the previous sections of this process mapping tutorial:

- Introduction to process mapping

- Process Mapping Tasks - identifying parts of the work and how they relate to each other

- Process Mapping Causes/Events - why the work happens when it does

- Process Mapping Roles - who does the work

Previous steps

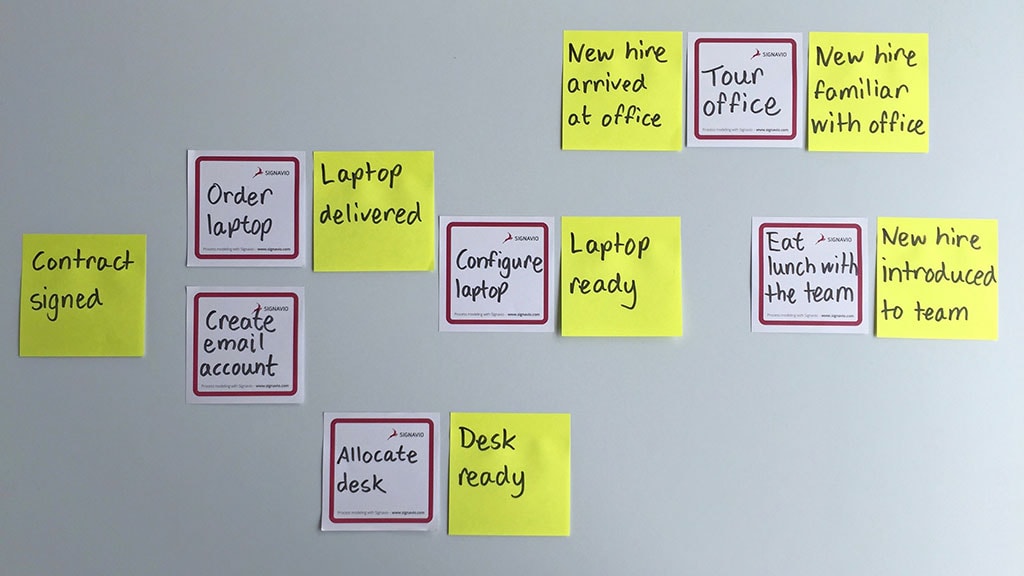

The previous parts of this tutorial focused on describing a process by identifying the tasks, events and roles that make up a timeline of work that contributes to the process goal. In a process mapping session, you can use sticky notes on a table or wall to facilitate working on this in a group.

One way to use the result of a process mapping session is to consider how you might improve the process by reducing the amount of work required each time you perform the process. To start simply, compare how the different tasks contribute to the process goal.

Value-creating tasks

In the onboarding process, some of the tasks directly help the new hire’s introduction to the company. The new employee directly benefits from meeting the team.

Some tasks directly contribute to the process goal - they create value. We sometimes talk about ‘value-creating activities’ - what the customer cares about. After all, the end customer - or the new hire in the onboarding example - doesn’t care what your process is: they’re only interested in the result.

There may also be optional tasks in the process. Touring the office helps the new hire, but the process goal would still be achieved without it, and the new hire could figure out where everything is at their own pace. Optional tasks are the nice-to-haves that aren’t part of the minimum viable process. Their value lies in between that of value creating tasks and those that are just unnecessary hassle.

Hassle and waste

Meanwhile, the new hire needs a new laptop to use for work. However, the benefits of someone else ordering and configuring the laptop are indirect. In an ideal world, a preconfigured laptop would already be available, and those tasks would not be necessary.

The first part of this hassle is the need to physically move the laptop from its supplier to the new employee’s desk, i.e. transportation. This ordering and purchase process also includes a transfer of ownership that requires ‘paperwork’, i.e. administration or bureaucracy. The second part - configuring the laptop - is a different kind of hassle, a kind of transformation.

Ideally, some of the tasks in a process wouldn’t be necessary - they’re unnecessary hassle. We sometimes call these tasks ‘waste’, to indicate that these tasks waste a precious resource: your time.

There are different kinds of hassle: over-production, inventory, waiting, storage, transformation, processing, rework, transportation and bureaucracy.

Improving process performance by reducing waste

As soon as you start thinking about some tasks as waste, you will naturally try to think of ways to reduce the waste. This isn’t easy though: you might work out that you could avoid the need to order a new laptop by having laptops in stock, but then you would be replacing the transportation waste with inventory, another kind of waste.

The challenge to remove waste is still a worthy one, despite its difficulty, because removing waste tends to have the biggest impact on process costs and performance. The onboarding process may require days or weeks of preparation and work, but you wouldn’t try to reduce this time by introducing the new hire to the team more quickly.

In general trying to perform value-creating tasks faster can be counter-productive. Cost reductions are likely to be limited, and offset by quality issues.

Identifying hassle and waste

There are no easy answers to reducing waste in a process, but you can still use a process mapping session to start a conversation, which is a good first step.

- Discuss each process task.

- Decide if each task creates value, represents waste or is a nice-to-have.

- Mark tasks that represent waste or replace them using different colour sticky notes.

- Discuss how you could remove waste and optional tasks from the process.

Removing waste is an advanced topic, and perhaps the interesting part of your job. Don’t expect process mapping to do more than start a useful discussion.

Next steps

The final step in process mapping is to evaluate what you have learned, and consider how this relates to real business process management as part of your daily work.

- Process Mapping Conclusions - lessons learned, software tools, next steps.