Business Process Management Methodologies

Learn about the most common process improvement methodologies used in BPM—from Lean and Six Sigma to the BPM lifecycle model—and how to apply them effectively across teams.

Learn about the most common process improvement methodologies used in BPM—from Lean and Six Sigma to the BPM lifecycle model—and how to apply them effectively across teams.

Business process management (BPM) methodologies provide structured approaches to analyzing, improving, and governing how work gets done. While every organization manages processes in some form, formal methodologies bring consistency, repeatability, and measurable outcomes to the effort.

They’re not just theoretical models. These frameworks are applied every day to streamline operations, reduce costs, improve compliance, and enable scale. In many cases, process improvement methodologies—like Lean, Six Sigma, or Kaizen—are adapted into broader process lifecycle initiatives to drive continuous value.

BPM teams and roles—such as business process analysts, managers, and owners—rely on these approaches to create shared understanding, align cross-functional work, and ensure improvements stick over time. Whether your organization is implementing new systems, undergoing digital transformation, or simply maturing its operations, having a structured methodology in place increases the likelihood of success.

→ See related: What is the Value of Business Process Management?

Despite their different origins and approaches, all process improvement methodologies share a common goal: making work more efficient, measurable, and aligned with business objectives. Whether you're removing waste, reducing variation, improving customer experiences, or introducing automation, methodologies provide a structured way to do it.

At their core, process management and improvement methodologies help organizations:

Methodologies provide a repeatable cycle that prevents “firefighting mode.” Instead of reacting to problems, teams learn to continuously analyze, adjust, and improve processes in a structured way.

You don’t need to wait for a full-scale transformation to benefit from a methodology. Even small, targeted improvements gain from having structure.

Practical way to start is to run a pilot project before scaling a methodology across the enterprise. For instance, apply Lean in one procurement process, measure the result, and then decide whether to expand.

It’s common to confuse BPM methodologies with execution platforms. Methodologies set the approach, while tools make it easier to execute.

Without a methodology, software risks being underused—features like dashboards or modeling libraries may never translate into business outcomes. Without tools, methodologies can remain stuck in workshops and binders.

Combining both ensures that improvements are practical, governed, and embedded in daily operations.

Below are the most widely used methodologies that help organizations design, implement, and optimize their business processes.

Each of these frameworks has a specific focus and is suited to different organizational needs and maturity levels.

Core Focus: End-to-end management of business processes

Best for: Organizations establishing a foundational BPM practice

The BPM lifecycle is a structured, iterative model that covers the complete process journey. It includes five key stages:

This model is tool-agnostic and can be applied across industries. It supports both strategic initiatives and daily operational improvements, offering flexibility and repeatability at scale.

Core Focus: Eliminating waste and improving flow

Best for: Streamlining operations and improving customer value

Originating from manufacturing (Toyota Production System), Lean helps organizations deliver more value with fewer resources. It focuses on:

Lean is widely used in healthcare, logistics, and service sectors to improve speed and efficiency without compromising quality.

Core Focus: Reducing process variation and improving quality

Best for: Organizations focused on data-driven performance improvement

Six Sigma uses statistical tools and the DMAIC cycle (Define, Measure, Analyze, Improve, Control) to improve processes. It is especially helpful for:

It often requires certification (e.g., Green Belt, Black Belt) and is common in industries like finance, manufacturing, and telecommunications.

Core Focus: Combining Lean speed with Six Sigma quality

Best for: Companies seeking both efficiency and precision

This hybrid approach merges the waste-reduction mindset of Lean with the analytics-driven rigor of Six Sigma. Lean Six Sigma enables:

It’s widely adopted in enterprise environments where both speed and compliance are essential.

Core Focus: Continuous, incremental improvement

Best for: Building a culture of improvement at all levels

Kaizen, meaning "change for better" in Japanese, encourages all employees to regularly suggest small changes. While simple, this approach builds long-term momentum. Benefits include:

It’s frequently used in Lean and Agile cultures and complements other methodologies well.

Core Focus: Organization-wide commitment to quality

Best for: Enterprises aligning quality, culture, and performance

TQM integrates quality principles across the company. It emphasizes:

Though less common as a standalone method today, TQM influenced the rise of ISO standards and is still a reference for governance-focused organizations.

Core Focus: Improving system performance by addressing bottlenecks

Best for: Environments where one process stage limits the entire system

TOC helps organizations identify and elevate constraints (bottlenecks) that hinder output. It’s useful for:

It’s often used alongside Lean or in production-heavy industries.

Core Focus: Iterative, collaborative, and adaptive process improvement

Best for: Digital teams and dynamic business environments

Agile BPM blends Agile project management with BPM practices. It allows teams to:

Agile BPM is growing in relevance, especially in tech, finance, and organizations with fast-changing needs.

In addition to the major methodologies above, several other frameworks are used either in niche industries or to complement broader process improvement efforts. These approaches may not be as widely adopted across all business units but provide value in specific domains, especially IT and compliance-heavy environments.

These complementary frameworks are often layered on top of—or used in conjunction with—broader BPM methodologies, especially in organizations where IT governance, regulatory compliance, or enterprise-wide consistency is critical.

There is no one-size-fits-all methodology. The right approach depends on your organization’s process maturity, strategic goals, industry requirements, and team capabilities. Some organizations even blend multiple methodologies—such as combining Lean with BPMN modeling or applying Six Sigma tools within an Agile process framework.

The key is to choose a method that fits your reality rather than forcing the organization into a rigid mold and factor these in:

Organizations at different maturity stages need different levels of structure. A start-up or a business scaling rapidly may not have the resources for formal governance and will gain more from lightweight methods such as Agile sprints or PDCA cycles, where improvements can be rolled out quickly and tested in real time.

By contrast, a global enterprise with thousands of employees and strict audit requirements may need the discipline of the BPM lifecycle or ISO-based frameworks, where process ownership, documentation, and compliance checkpoints are formalized.

The right methodology often depends on what you want to achieve:

Methodologies must fit the people expected to use them. A small operations team without certification may struggle with Six Sigma’s statistical rigor or TOGAF’s enterprise architecture approach, but they can quickly apply Agile ceremonies (like retrospectives) or PDCA loops to drive change.

In contrast, a mature operations excellence team may invest in training and certification to fully implement Six Sigma, Lean Six Sigma, or ITIL practices across the enterprise.

The availability of supporting software often determines how quickly a methodology delivers results. For example, the BPM lifecycle is easier to adopt when supported by a modeling platform like SAP Signavio Transformation Suite, which provides governance, notation standards, and repositories.

Lean principles can be reinforced through dashboards and KPIs in analytics tools, while Agile teams often rely on workflow automation platforms for iterative delivery.

Conceptual frameworks without strong tooling support may remain theoretical unless supplemented by practical systems.

Hybrid models are increasingly common in complex enterprises. Few organizations follow one methodology exclusively because business challenges often span multiple needs.

What matters most is not textbook adherence but whether the chosen approach helps your organization analyze, improve, and govern processes with measurable business outcomes. A methodology is only successful if it delivers results that employees can adopt, leaders can measure, and the business can sustain over time.

While business process management (BPM) methodologies offer structure and value, applying them incorrectly—or at the wrong time—can limit their impact or even cause resistance across the organization.

Understanding the common challenges helps teams avoid missteps and apply the right methodology for the right context.

Not every methodology fits every organization. For example, Lean might be ideal for frontline operational improvements, while BPM or Six Sigma may be better suited for structured, high-complexity processes.

Start with a clear definition of business goals and process maturity before selecting a methodology. If the goal is efficiency, Lean may fit; if compliance is the priority, ITIL or ISO works better. Use maturity assessments and pilot projects to test fit before scaling.

Some teams fall into the trap of using methodologies as an end in themselves rather than a means to an outcome.

The goal isn’t to have the best diagrams—it’s to make work simpler, faster, and more reliable. Apply a “fit-for-purpose” rule: document processes only to the level of detail needed to drive decisions or improvements. Use tools like BPM tools for governance, but set modeling standards that balance thoroughness with usability.

Even the best methodology won’t succeed without cultural support.

Involve employees early through workshops, feedback loops, and pilots. Position the methodology as a tool to make their work easier, not harder. Combine this with change management practices—training, communication, and leadership sponsorship—to create buy-in.

Sustainable BPM requires ongoing executive support. Without it, teams struggle to prioritize improvement work, secure resources, or enforce standards.

Secure a C-level sponsor such as the COO or CIO to champion BPM initiatives. Tie outcomes directly to strategic goals (e.g., cost savings, compliance scores, transformation milestones) so executives see BPM as a lever for business success rather than a side project.

A common pitfall is treating BPM as a project with a beginning and an end rather than a continuous capability.

Position BPM as an ongoing discipline embedded into the process lifecycle. Establish continuous monitoring, governance structures, and improvement cycles so the organization can adapt as circumstances change. This ensures BPM becomes a sustainable capability rather than a temporary project.

BPM methodologies are shifting toward greater flexibility as organizations adapt to AI, data-driven decision-making, and agile operating models. Instead of following one strict method, teams increasingly blend elements of Lean, Six Sigma, and lifecycle models, using process mining and real-time insights to guide their choices.

AI accelerates this shift by detecting inefficiencies, predicting outcomes, and assisting with modeling and governance, while agile practices encourage faster, iterative improvements that engage users earlier and reduce risk.

Together, these trends point to a future where BPM methodologies are less about rigid frameworks and more about enabling continuous, adaptive improvement.

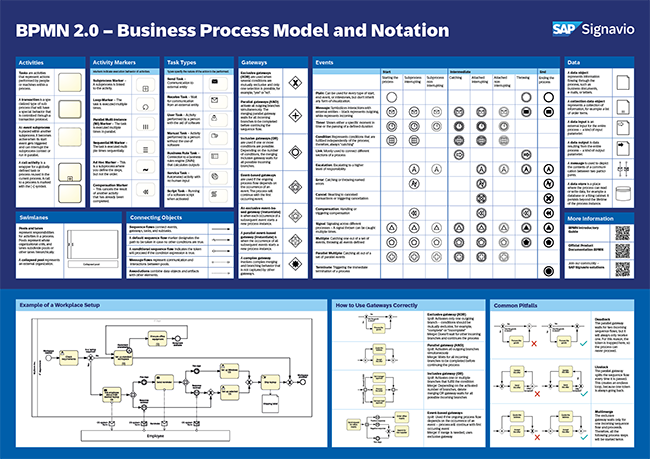

Get the most important standards, ready for you to modify and adapt according to your own standards and organizational needs.