But a lot has changed over the past few years – and these changes are accelerating rapidly. Customers and investors are more enlightened about climate issues and demanding that companies they do business with take steps to protect the environment for future generations. Governments around the world are banding together, joining pacts, and mandating change through environmental, social, and governance (ESG) commitments and regulations. Failure in this area is not only bad for company brands (especially in today’s social media driven environment), but also the bottom line.

How are manufacturers responding?

A new study, “The Transformation Mindset – New Levers for Growth and Efficiency,” conducted by the SAP Insights research center with senior leaders of 10,500 midsize businesses, sheds light on this topic. in the full report it was found that among respondents in manufacturing companies, 32% showed “Increasing sustainability in products and services” as a top-three priority for driving revenue growth. This suggests that manufacturers and their customers are at a tipping point. Being green costs the business more – and yet companies are seeing this as a strategy for increasing revenues because customers are demanding it. Given that 35% of manufacturers cited “Improving brand recognition and reputation” as a top-three priority for driving revenue growth, one can infer that becoming more sustainable will simultaneously help them boost their brand and reputation.

The challenge, of course, will be to make sustainability profitable and scalable. To make this work, manufacturers will need to better understand their processes and operations and find new ways to make more sustainable processes less costly and more efficient. When the SAP Insights survey asked manufacturers about the kinds of process changes required to achieve their business goals, respondents cited increasing flexibility and adaptability to change most frequently (37%). Nearly as frequently cited were changes such as increasing the speed of business processes (35%), reducing the cost of operations (35%), and increasing the level of automation (34%).

These are substantive changes that don’t come easy, especially if you have lots of legacy systems, siloed processes and data, manual and paper-based ways of working, and deep-seated departmental resistance standing in your way. Not only do people fear change, but your underlying infrastructure may be rigid, and interdependent tasks in end-to-end processes may be fragile. Change one step, and there may be unintended consequences.

How is your company exploring options to improve sustainability?

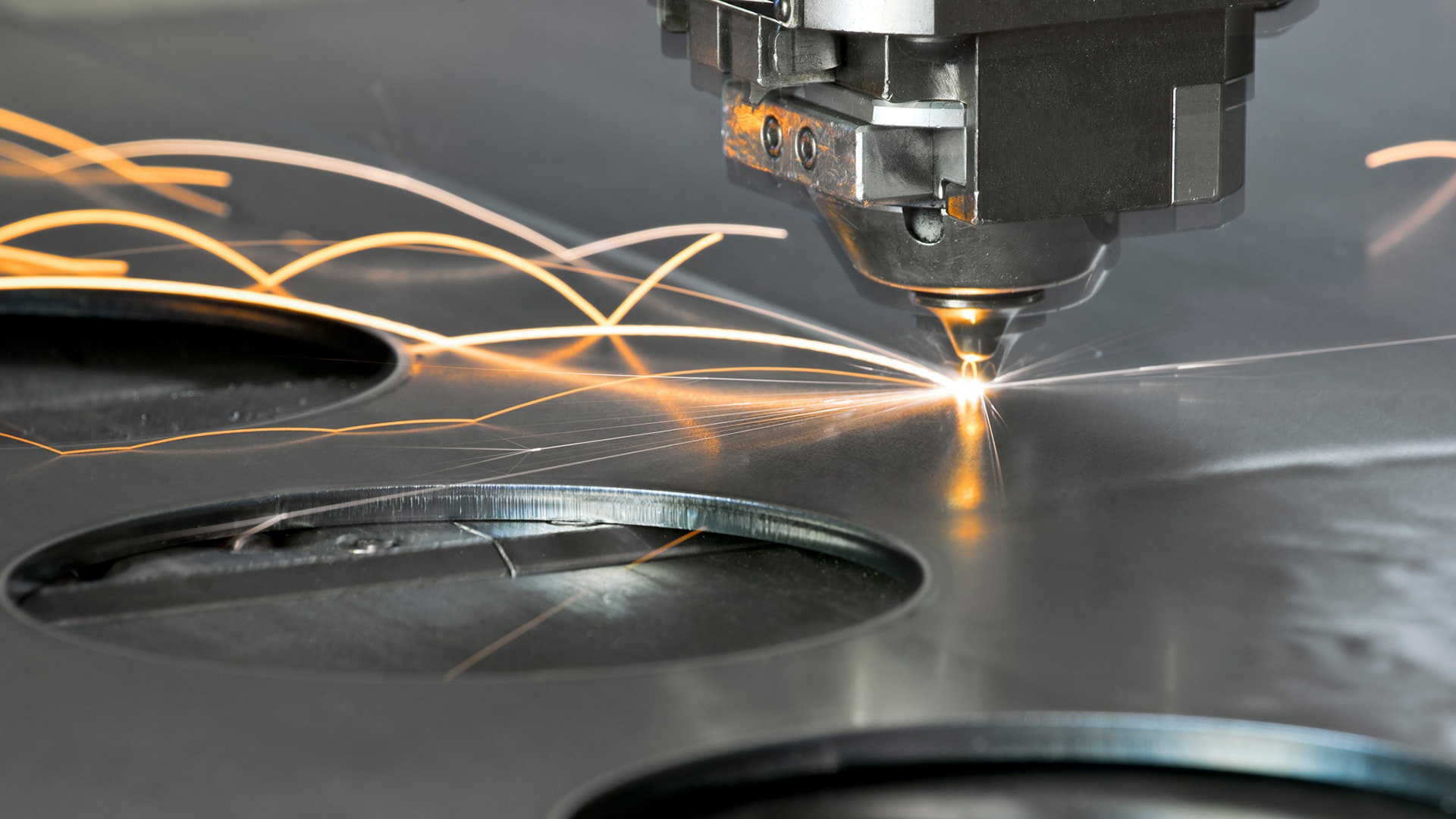

For example, if you work in the automotive industry, are you looking building digital supply chains that support circular manufacturing where car makers, suppliers, and service providers collaborate to drive reusage of parts and materials? They all benefit from savings – for example, through a reduction in CO2 emissions or costs. Are you planning to invest in smart factories that intelligently sense, respond, and automate key processes to minimize waste and produce more at a lower cost?

And if you work for an industrial manufacturer, are you exploring ways to make operating more sustainable – and make sustainability more profitable?

One thing is clear: to succeed, you’ll need to continuously improve your processes. This means business process transformation must become a core competency within your business.

Business process transformation is a process-oriented approach that focuses on achieving – and managing – process transformation and excellence in a scalable, collaborative, and data-driven way. Changes are driven collaboratively, involving those closest to the work, not just executives, to address fears, ensure you get to the best outcome, and drive adoption. Once processes are launched, they are monitored for compliance and continuous improvement.

Want to learn more?

Download the new paper from SAP on “Operationalizing Continuous Process Innovation for Discrete Manufacturers: What’s Needed to Understand, Improve, and Transform Business Processes Rapidly and at Scale ".